-

Rectangular tubes are widely used

Common materials of welded square pipes are: Q235A, Q235C, Q235B, 16Mn, 20#, Q345, L245, L290, X42, X46, X60, X80, 0Cr13, 1Cr17, 00cr19ni11, 1Cr18Ni9, 0cr18ni11nb, etc.

-

A106B A53 S45C A333GR.6 thick wall steel pipe quality assurance

The production process of thick-walled seamless steel pipes can be divided into four basic methods: cold drawing, cold rolling, hot rolling, and thermal expansion. Uses are divided into seamless steel pipes for structure; seamless steel pipes for transportation; seamless steel pipes for boilers; high-pressure seamless steel pipes for boilers; high-pressure seamless steel pipes for fertilizer equipment; seamless steel pipes for geological drilling; seamless steel pipes for oil drilling; Seamless steel pipes for petroleum cracking; seamless steel pipes for ships; cold-drawn cold-rolled precision seamless steel pipes; various alloy pipes. Seamless steel pipes are expressed in terms of outer diameter and wall thickness. Thick-walled seamless steel pipes are mainly used for machining, coal mines, hydraulic steel, and many other purposes.

Hot-rolled thick-walled seamless steel pipes, cold-rolled thick-walled seamless steel pipes, cold-drawn thick-walled seamless steel pipes, extruded thick-walled seamless steel pipes, and stainless steel seamless steel pipes for pipe jacking structures (GB/T14975-2002) are used for Seamless steel pipes of general structure and mechanical structure are widely used in the hot-rolled (extruded, expanded) and cold-rolled (extruded, expanded) and cold-rolled stainless steel of corrosion-resistant pipes and structural parts and parts in the chemical, petroleum, textile, medical, food, machinery and other industries. Drawing (rolling) seamless steel tubes.

Stainless steel seamless steel pipes for fluid transportation (GB/T14976-2002) are general seamless steel pipes used to transport water, oil, gas and other fluids. They are usually hot-rolled (extruded, expanded) and cold drawn (rolled) made of stainless steel. ) Seamless steel pipe.

Shaped seamless steel pipe is a general term for seamless steel pipes with cross-sectional shapes other than round pipes. According to the different shape and size of the steel pipe section, it can be divided into equal wall thickness special-shaped seamless steel pipe (code D), unequal wall thickness special-shaped seamless steel pipe (code BD), variable diameter special-shaped seamless steel pipe (code BJ). Special-shaped seamless steel pipes are widely used in various structural parts, tools and mechanical parts. Compared with round pipes, special-shaped pipes generally have larger moments of inertia and section modulus, and have greater bending and torsion resistance, which can greatly reduce structural weight and save steel.

Seamless steel pipe for structure (GB/T8162-2008) is a seamless steel pipe used for general structure and mechanical structure.

Seamless steel pipe for fluid transportation (GB/T8163-2008) is a general seamless steel pipe used to transport water, oil, gas and other fluids.

Seamless steel pipes for low and medium pressure boilers (GB3087-2008) are used to manufacture superheated steam pipes, boiling water pipes for low and medium pressure boilers of various structures and superheated steam pipes for locomotive boilers, large smoke pipes, small smoke pipes and arched brick pipes. High-quality carbon structural steel hot-rolled and cold-drawn (rolled) seamless steel tubes.

Seamless steel pipes for high-pressure boilers (GB5310-2008) are high-quality carbon steel, alloy steel and stainless heat-resistant steel seamless steel pipes for the heating surface of water-tube boilers with high pressure and above.

High-pressure seamless steel pipes for fertilizer equipment (GB6479-2000) are high-quality carbon structural steel and alloy steel seamless steel pipes suitable for chemical equipment and pipelines with a working temperature of -40 to 400 ℃ and a working pressure of 10 to 30 Ma.

Seamless steel pipes for petroleum cracking (GB9948-2006) are seamless steel pipes suitable for furnace tubes, heat exchangers and pipelines in petroleum refineries.

Steel pipes for geological drilling (YB235-70) are steel pipes used for core drilling by geological departments. They can be divided into drill pipes, drill collars, core pipes, casing pipes and sedimentation pipes according to their uses.

Seamless steel pipes for diamond core drilling (GB3423-82) are seamless steel pipes for drill pipes, core rods, and casings used for diamond core drilling.

Petroleum drilling pipe (YB528-65) is a seamless steel pipe that is thickened inside or outside at both ends of oil drilling. Steel pipes are divided into two types: wire and non-wired. Wired pipes are connected by joints, and non-wired pipes are connected with tool joints by butt welding.

Carbon steel seamless steel pipes for ships (GB5213-85) are carbon steel seamless steel pipes used in the manufacture of Class I pressure piping systems, Class II pressure piping systems, boilers and superheaters. The working temperature of the carbon steel seamless steel pipe wall does not exceed 450℃, and the working temperature of the alloy steel seamless steel pipe wall exceeds 450℃.

Seamless steel pipes for automobile axle sleeves (GB3088-82) are high-quality carbon structural steel and alloy structural steel hot-rolled seamless steel pipes used in the manufacture of automobile axle sleeves and axle tubes of drive axle housings.

High-pressure oil pipes for diesel engines (GB3093-86) are cold-drawn seamless steel pipes used to manufacture high-pressure pipes for diesel engine injection systems.

Precision inner diameter seamless steel pipes for hydraulic and pneumatic cylinders (GB8713-88) are cold-drawn or cold-rolled precision seamless steel pipes with precise inner diameters for the manufacture of hydraulic and pneumatic cylinders.

Cold-drawn or cold-rolled precision seamless steel pipe (GB3639-83) is a cold-drawn or cold-rolled precision seamless steel pipe used for mechanical structures and hydraulic equipment with high dimensional accuracy and good surface finish. The use of precision seamless steel pipes to manufacture mechanical structures or hydraulic equipment can greatly save machining man-hours, increase material utilization, and at the same time help improve product quality. -

A106GR.B A53B A315B A178C SA210A fluid seamless steel pipe manufacturer

Fluid pipe is a kind of steel pipe with hollow section and no weld from beginning to end. Steel pipe has hollow section, which is widely used as a pipe for conveying fluid, oil, natural gas, gas, water and some solid materials.

-

Chinese 3PE anticorrosive steel pipe manufacturer

According to the calculation of relevant departments, generally, polyurethane insulated steel pipe can reduce the project cost by about 25% (using FRP as the protective layer) and 10% (using high-density polyethylene as the protective layer).

-

Customized square tubes of various specifications

Also known as square and rectangular cold-formed hollow section steel, referred to as square tube and rectangular tube, code names are f and j respectively.

-

High pressure stainless steel tube manufacturer

316L is a brand of stainless steel, AISI 316L is the corresponding American brand and Sus 316L is the corresponding Japanese brand. China’s unified digital code is s31603, the standard brand is 022cr17ni12mo2 (new standard), and the old brand is 00Cr17Ni14Mo2, which indicates that it mainly contains Cr, Ni and Mo, and the number indicates the approximate percentage.

-

A335 P12 A369 FP12 13CRMO44 A213 T12 alloy steel pipe

13CrMo44 alloy tube is used for the heating surface tube of low and medium pressure boiler (working pressure is generally not more than 5.88Mpa, working temperature is below 450℃); for high pressure boiler (working pressure is generally above 9.8Mpa, working temperature is 450℃~650℃ Between) heating surface pipes, economizers, superheaters, reheaters, petrochemical industry pipes, etc.

P12 alloy tube The alloy tube can be roughly divided into three types: carburized, quenched and tempered and nitrided steel. It has better comprehensive mechanical properties than high-quality carbon structural steel tubes. P12 alloy tubes are mainly used for heating surface tubes of low and medium pressure boilers; heating surface tubes for high pressure boilers, economizers, superheaters, reheaters, petrochemical industry tubes, etc. -

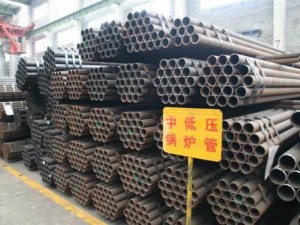

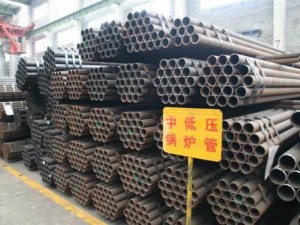

Warranty of genuine boiler tube manufacturer

A large number of genuine high-pressure boiler tubes are in stock.

High pressure seamless steel pipe and high pressure boiler pipe are a kind of boiler pipe, belonging to the category of seamless steel pipe. The manufacturing method is the same as that of seamless pipe, but there are strict requirements for the steel grade used in the manufacture of steel pipe.

-

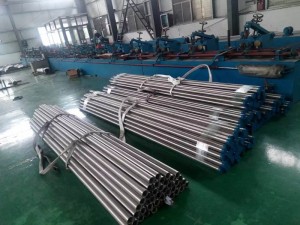

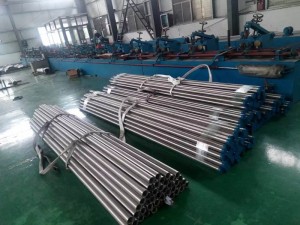

Spot sales of precision bright tubes

Cold rolled seamless pipe (GB3639-2000) is a cold drawn or cold rolled precision seamless steel pipe with high dimensional accuracy and good surface finish for mechanical structure and hydraulic equipment.

-

Warranty sales of 4130 alloy steel pipe manufacturer

4130 structural steel has high strength and toughness, high hardenability, and the critical hardening diameter in oil is 15~70mm; the thermal strength of steel is also good, with sufficient high temperature strength below 500℃, but at 550℃ Its strength decreases significantly; when the alloy element is at the lower limit, the welding is quite good, but when the alloy element is close to the upper limit, the weldability is medium, and it needs to be preheated to above 175℃ before welding; the machinability of steel is good, and the plasticity during cold deformation is medium; The range of 300~350℃ has the first type of temper brittleness; there is a tendency to form white spots. This kind of steel is usually used in the quenched and tempered state. When the carbon content is the lower limit, the steel can also be used as a carburizing steel that requires a higher core strength. In the medium-sized machinery manufacturing industry, it is mainly used to manufacture quenched and tempered parts with large cross-sections and working under high stress conditions, such as shafts, spindles, and high-load control wheels, bolts, studs, gears, etc.; in the chemical industry Used to manufacture welded parts, welded structures composed of plates and pipes, and high-pressure pipes that work in a nitrogen-hydrogen medium with a temperature not exceeding 250°C; used in the manufacturing of steam turbines and boilers to make fasteners that work below 450°C, Flanges and flange covers subject to high pressure below 500°C.

Carbon C: 0.28~0.33

Silicon Si: 0.15~0.35

Manganese Mn: 0.40~0.60

Sulfur S: allowable residual content ≤0.040

Phosphorus P: allowable residual content ≤0.035

Chromium Cr: 0.80~1.10

Nickel Ni: allowable residual content ≤0.030

Copper Cu: allowable residual content ≤0.030

Molybdenum Mo: 0.15~0.25

Tensile strength σb (MPa): ≥930(95) Yield strength σs (MPa): ≥785(80)

Elongation δ5 (%): ≥12

Reduction of area ψ (%): ≥50

Impact energy Akv (J): ≥63

Impact toughness value αkv (J/cm2): ≥78(8)

Hardness: ≤229HB

Sample size: sample blank size is 25mm

Heat treatment specification: quenching at 880°C, water cooling, oil cooling; tempering at 540°C, water cooling, oil cooling. -

High pressure resistant boiler tube manufacturer genuine spot

Executive standard for medium and low pressure boiler tubes: GB3087-1999 seamless steel tubes for low and medium pressure boilers.

-

Anti corrosion and thermal insulation steel pipe manufacturer

High temperature prefabricated directly buried insulation pipe is a kind of directly buried prefabricated insulation pipe with good insulation performance, safety and reliability and low project cost.

- Call Support 0086-18365819992

- Email Support sales@weichuanmetal.com