Top Quality Tiangang 3087 Seamless Steel Pipe - ASTM A53 A283 A106 A179 A210 galvanized steel pipe – Weichuan

Top Quality Tiangang 3087 Seamless Steel Pipe - ASTM A53 A283 A106 A179 A210 galvanized steel pipe – Weichuan Detail:

Because the hot-dip galvanized seamless steel pipe is hot-dip galvanized, the amount of galvanized is very high. The average thickness of galvanized layer is more than 65 microns, and its corrosion resistance is much different from that of hot-dip galvanized pipe. Regular galvanized pipe manufacturers are allowed to use cold galvanized pipes as water and gas pipes. The galvanized layer of cold galvanized steel pipe is an electroplating layer, and the zinc layer is separated from the steel pipe substrate. The zinc layer is thin, and the zinc layer is simply attached to the steel pipe matrix, which is easy to fall off. Therefore, its corrosion resistance is poor. In new houses, it is forbidden to use cold galvanized steel pipes as water supply steel pipes. After pickling, API seamless steel pipes are cleaned in ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank. In order to ensure quality, electro galvanizing (cold plating) is mostly not used. Only those small enterprises with small scale and old equipment use electro galvanizing, of course, their price is relatively cheap. The Ministry of construction has officially eliminated the backward cold galvanized pipe, which will not be electro galvanized in the future. It is to make the molten metal react with the iron matrix to produce an alloy layer, so as to combine the matrix and the coating. Hot dip galvanizing is to pickle the steel pipe first, in order to remove the iron oxide on the surface of the steel pipe, and then send it to the hot dip galvanizing tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. 1. Medium plate unit: it mainly produces wide and thick plates for the production of longitudinal submerged arc welded pipes. The longitudinal submerged arc welded pipes are of reliable quality and are widely used in the main line of oil and gas high-pressure transmission.

Steckel Mill: Steckel mill includes a reciprocating roughing mill and a 4-high reciprocating finishing mill. Two hot coil mills are installed on the conveyor lines on both sides of the finishing mill. The output roller table usually includes a laminar cooling system and a coiling station. On the steckel mill, the thermomechanical history of the whole length of stainless steel stamping elbow pipe fittings changes significantly, especially in the production of micro stainless steel stamping elbow pipe fittings, which will strongly affect the recrystallization degree, grain growth and precipitation on the finishing mill, and lead to drastic changes in the final microstructure and properties of the whole length of stainless steel stamping elbow pipe fittings

Semi continuous mill: including 1 Steckel mill and 5 finishing mills. On a semi continuous rolling mill, the hot rolling of pipe fittings in finishing passes is essentially constant from one end to the other. The time between passes on the finishing mill is usually less than 3S.

CSP continuous casting and rolling: for low carbon manganese steel containing niobium, vanadium and titanium composite Microalloying on CSP production line, appropriate controlled rolling, controlled cooling and coiling processes can ensure that the mechanical properties and microstructure of pipe fittings meet the technical requirements of modern X60 stainless steel stamping elbow and the development trend of modern stainless steel stamping elbow pipe fittings. China’s CSP continuous casting and rolling production line has developed X60 stainless steel stamping elbow fittings, while other CSP manufacturers in the United States and abroad have developed and produced high-grade stainless steel stamping elbow fittings X60, X65 and even X70. The process feature is that there is central segregation in continuous casting thin slab. The elimination of central segregation in continuous casting thin slab by galvanized seamless steel pipe is the key technical problem to further improve the quality of stainless steel stamping elbow fittings. The plates used for stainless steel stamping elbow mainly used A3 and 16Mn produced by Angang and other manufacturers in the 1960s and 1970s. With the increase of pipe diameter and transmission pressure, The strength of pipe fitting plate can not meet the requirements. After the 1980s, all petroleum welded pipe parts factories began to use pipeline steel plates produced according to American API standards. At that time, due to the immature technology of domestic stainless steel stamping elbow plate manufacturers, imported plates were mainly used.

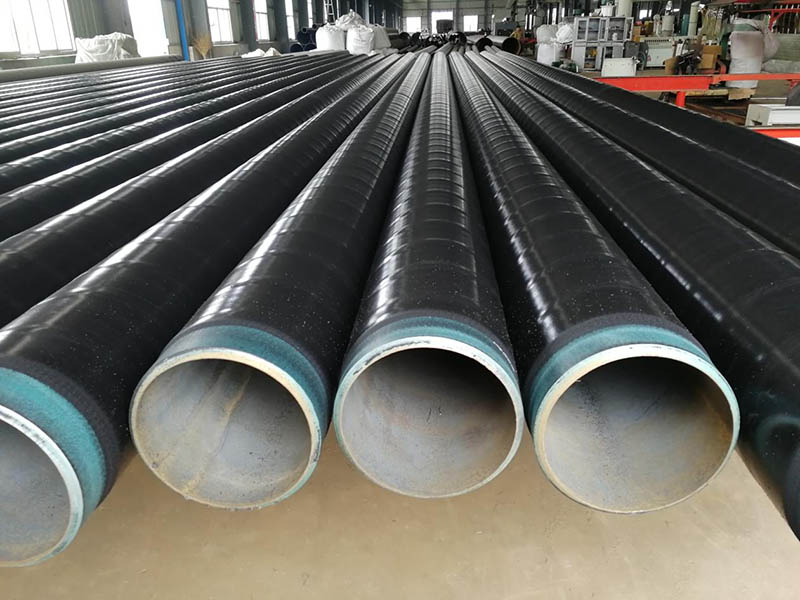

Product detail pictures:

Related Product Guide:

Sticking towards the theory of "Super Good quality, Satisfactory service" ,We are striving to become a superb business enterprise partner of you for Top Quality Tiangang 3087 Seamless Steel Pipe - ASTM A53 A283 A106 A179 A210 galvanized steel pipe – Weichuan, The product will supply to all over the world, such as: Melbourne, Orlando, Indonesia, With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our products in China!

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!