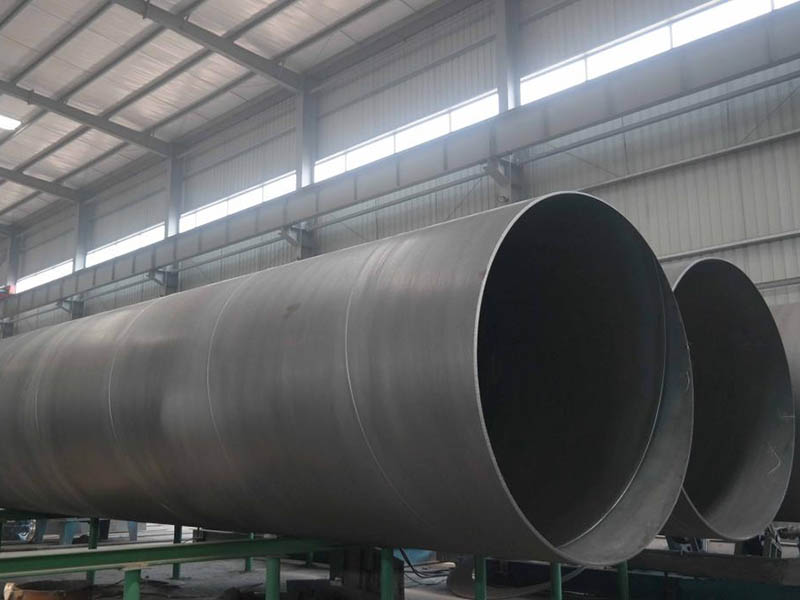

Large diameter spiral steel pipe manufacturer

a. During the forming process, the steel plate is deformed evenly, the residual stress is small, and the surface is not scratched. The processed spiral steel pipe has greater flexibility in the size and specification range of diameter and wall thickness, especially in the production of high-grade thick wall pipe, especially small and medium-sized thick wall pipe, which has incomparable advantages over other processes, and can meet more requirements of users in the specification of spiral steel pipe.

b. The advanced double-sided submerged arc welding process can realize welding at the best position, which is not easy to have defects such as misalignment, welding deviation and incomplete penetration, and it is easy to control the welding quality.

c. 100% quality inspection is carried out on the steel pipe, so that the whole process of steel pipe production is under effective detection and monitoring, and the product quality is effectively guaranteed.

d. All equipment of the whole production line has the function of networking with the computer data acquisition system to realize real-time data transmission, and the technical parameters in the production process are monitored by the central control room.

The spiral steel pipe shall be subject to mechanical property test, flattening test and flaring test before leaving the factory, and shall meet the requirements specified in the standard. The quality inspection method of straight seam steel pipe is as follows:

1. Judging from the surface, that is, in the appearance inspection. The appearance inspection of welded joints is a simple and widely used inspection method. It is an important content of finished product inspection. It is mainly to find the defects on the weld surface and dimensional deviation. Generally, inspection is carried out through visual observation with the help of standard template, gauge, magnifying glass and other tools. If there are defects on the weld surface, there may be defects inside the weld.

2. Test of physical method: physical test method is a method of measuring or testing by using some physical phenomena. Nondestructive testing is generally used to inspect the internal defects of materials or workpieces. NDT includes ultrasonic flaw detection, radiographic flaw detection, penetrant flaw detection, magnetic flaw detection, etc.

3. Strength test of pressure vessels: in addition to the tightness test, strength test shall also be carried out for pressure vessels. There are two common types: hydrostatic test and pneumatic test. They can test the weld tightness of vessels and pipes working under pressure. Pneumatic test is more sensitive and faster than hydraulic test. At the same time, the tested products do not need drainage treatment, which is especially suitable for products with difficult drainage. But the test is more dangerous than hydrostatic test. During the test, corresponding safety technical measures must be observed to prevent accidents during the test.

4. Compactness test: for welded vessels storing liquid or gas, the non compactness defects of welds, such as penetrating cracks, pores, slag inclusion, incomplete penetration and loose structure, can be found by compactness test. The compactness test methods include kerosene test, water carrying test, water impact test, etc.

5. For hydrostatic test, each steel pipe shall be subject to hydrostatic test without leakage. The test pressure shall be calculated as P = 2st / D, where s - Test Stress MPa of hydrostatic test, and the test stress of hydrostatic test shall be selected as 60% of the minimum yield value specified in the corresponding steel belt standard (Q235 is 235mpa). Pressure stabilization time: D. the spiral weld of steel pipe for fluid transmission shall be subject to X-ray or ultrasonic inspection (20%).

According to the quality inspection results of spiral steel pipe, spiral steel pipe is usually divided into three categories: qualified products, repaired products and waste products. Qualified products refer to spiral steel pipes whose appearance quality and internal quality meet relevant standards or technical conditions for delivery acceptance; Repaired products refer to spiral steel pipes whose appearance quality and internal quality do not fully meet the standards and acceptance conditions, but are allowed to be repaired, and can meet the standards and acceptance conditions after repair; Scrap refers to the spiral steel pipe whose appearance quality and internal quality are unqualified, which is not allowed to be repaired or still fails to meet the standards and acceptance conditions after repair.

Waste products are divided into internal waste and external waste. Internal waste refers to the waste spiral steel pipe found in the foundry or foundry workshop; External waste refers to the waste found after delivery of spiral steel pipe, which is usually exposed in the process of machining, heat treatment or use, and its economic loss is much greater than that of internal waste. In order to reduce external waste, the spiral steel pipes produced in batches should be sampled for experimental heat treatment and rough processing before leaving the factory, and potential spiral steel pipe defects should be found in the spiral steel pipe plant as far as possible, so as to take necessary remedial measures as soon as possible.

1) Small and medium-sized section steel, wire rod, reinforcement, medium diameter steel pipe, steel wire and steel wire rope can be stored in a well ventilated shed, but they must be covered and padded.

2) Some small steel, steel sheet, steel strip, silicon steel sheet, small-diameter or thin-wall steel pipe, various cold-rolled and cold drawn steel and metal products with high price and easy corrosion can be stored in the warehouse.

3) The site or warehouse for storing spiral steel pipe products shall be in a clean and unobstructed place, away from factories and mines that produce harmful gas or dust. Weeds and all sundries shall be removed on the site to keep the steel clean.

4) Large section steel, rail, steel plate, large-diameter steel pipe, forging, etc. can be stacked in the open air.

5) It is not allowed to stack with acid, alkali, salt, cement and other materials that are corrosive to steel in the warehouse. Different types of steel shall be stacked separately to prevent confusion and contact corrosion.

6) The warehouse shall be selected according to geographical conditions. Generally, it adopts ordinary closed warehouse, that is, the warehouse with roof, enclosure, tight doors and windows and ventilation devices.

7) The warehouse shall be ventilated in sunny days, closed in rainy days to prevent moisture, and always maintain a suitable storage environment.