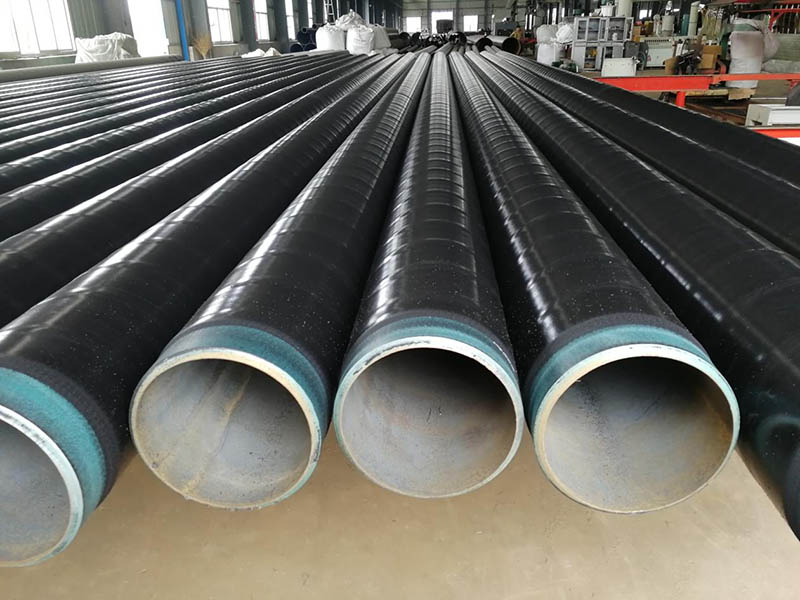

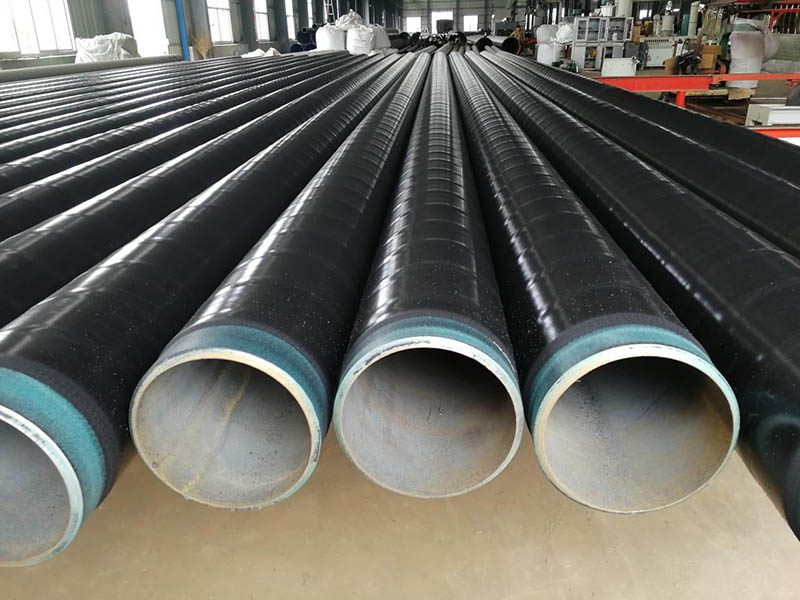

Corrosion resistant high strength steel pipe factory

The base material of 3PE anticorrosive steel pipe includes seamless steel pipe, spiral steel pipe and straight seam steel pipe. Three layer polyethylene (3PE) anticorrosive coating has been widely used in petroleum pipeline industry because of its good corrosion resistance, water and gas permeability and mechanical properties. The anti-corrosion coating of 3PE anti-corrosion steel pipe is very important for the service life of buried pipelines. Some pipelines of the same material are buried underground for decades without corrosion, and some leak in a few years. Because they use different external anti-corrosion coatings.

3PE anticorrosive steel pipe refers to the external anticorrosive steel pipe with 3-layer structural polyethylene coating (mapec), which is a commonly used anticorrosive pipe in China. Other anti-corrosion methods include ipn8710, FBE epoxy powder, epoxy coal tar pitch and so on. It generally refers to the anti-corrosion of the outer wall of steel pipe. Anti corrosion form of steel pipe outer wall.

First layer of epoxy powder (FBE > 100um)

The second layer of adhesive (AD) is 170 ~ 250um

The third layer of polyethylene (PE) is 1.8 ~ 3.7mm

In practice, the three materials are mixed and integrated into one, which is firmly combined with the steel pipe after processing to form an excellent anti-corrosion coating. Its processing methods are generally divided into winding type and circular die coating type.

3PE anticorrosive steel pipe coating (three-layer polyethylene anticorrosive coating) is a new anticorrosive steel pipe coating produced by skillfully combining 2PE anticorrosive coating in Europe and epoxy powder anticorrosive steel pipe coating (FBE) widely used in North America. It has been recognized and used all over the world for more than ten years.

The coating of 3PE anti-corrosion steel pipe is epoxy powder anti-corrosion coating in contact with the steel pipe surface, and the middle layer is copolymer adhesive with branch structure functional group. The surface layer is high-density polyethylene anti-corrosion coating.

The three P E anticorrosive coating combines the high impermeability and high mechanical properties of epoxy resin and polyethylene. So far, it is recognized as the best pipe anti-corrosion coating with the best effect and performance in the world, which has been applied in many projects.

SY / t0413-2002 standard is implemented in China and has been implemented since August 1, 2002. The standard mainly specifies polyethylene and high-density polyethylene, and the Vicat softening point is not less than 110 ℃; The thickness of the external anti-corrosion coating shall be determined according to the German standard din30670-1991 dominated by low and medium density polyethylene. The impact strength of 3PE anticorrosive coating is greatly improved. SY / t0413-2002 greatly improves the peel strength and impact resistance of 3PE anti-corrosion coating, clearly stipulates that according to the carbon black content of some special materials, the mechanical strength and weather resistance of 3PE anti-corrosion coating are guaranteed, and the sampling frequency of joint coating peel strength (i.e. the peel strength of heat shrinkable sleeve and heat shrinkable belt to primer steel) is increased.

For the purpose of 3PE anti-corrosion steel pipe, many people only know one thing and don't know the other. Its function really covers a wide range. It is suitable for underground water supply and drainage, underground shotcrete, positive and negative pressure ventilation, gas drainage, fire sprinkler and other pipe networks in coal mines. Process water, waste residue and return water transmission pipeline of thermal power plant. It has excellent applicability to the water supply pipeline of anti spray and sprinkler system. Cable protective sleeves for power, communication, expressway, etc. It is suitable for water supply of high-rise buildings, heat supply of heating network, tap water engineering, gas transmission, buried water transmission and other pipelines. Oil transmission pipeline, process pipeline for transporting corrosive media in chemical, pharmaceutical, printing and dyeing industries. Anti corrosion works of sewage treatment discharge pipe, sewage pipe and biological tank. It can be said that 3PE anti-corrosion steel pipe is essential in the current construction, and it is believed that through the extension of science and technology, it will have more brilliant achievements in the future.